As data centres grapple with soaring energy demands and pressing climate targets, Luca Rizzo, Global Industry Manager at ABB, explores why smarter cooling systems may hold the ultimate solution.

Data centres have long been an integral part of the physical infrastructure which supports the digital services the global economy relies on, from cloud computing to AI applications. However, their rapid expansion has led to significant energy consumption challenges.

Notably, data centres and data transmission networks account for 1-1.5% of global electricity consumption and 0.5% of CO₂ emissions, figures comparable to entire industries such as chemicals and aviation. This trend is expected to intensify, with projections indicating a 160% increase in data centre energy demand by 2030, reaching 3-4% of global energy consumption.

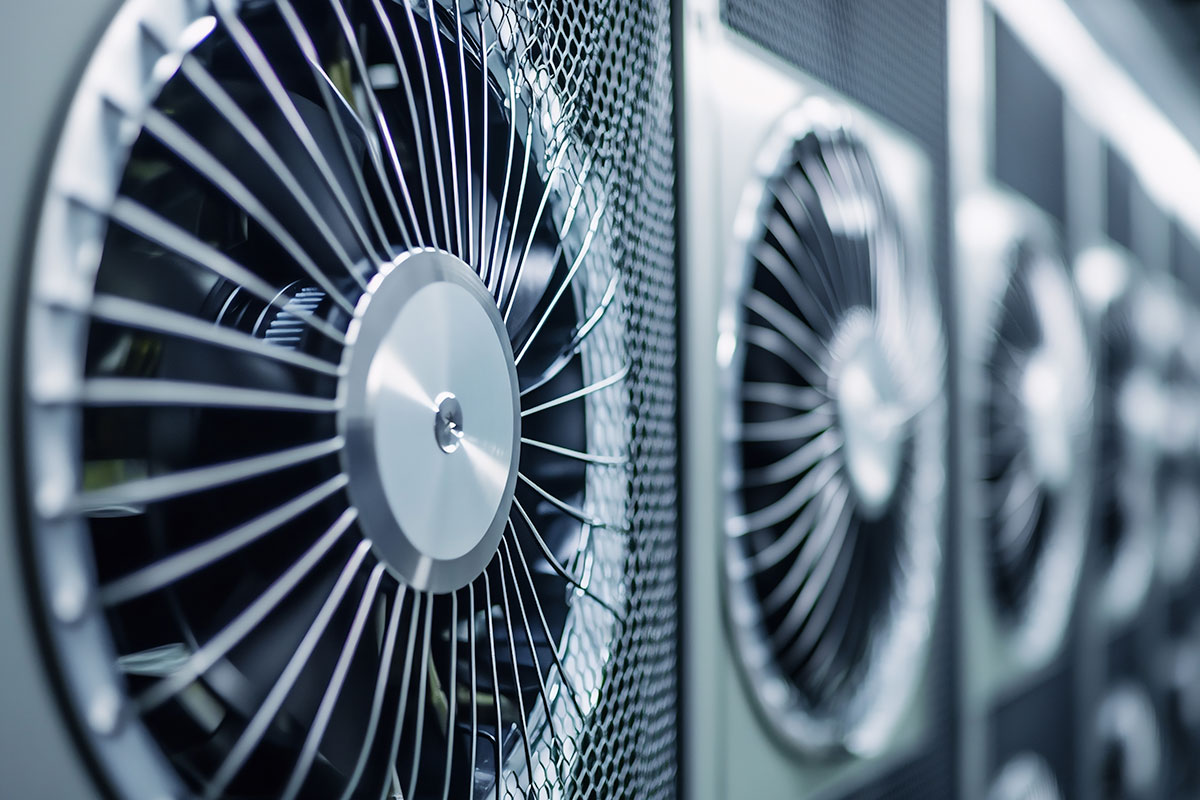

A substantial portion of this energy – around 40% – is dedicated to cooling systems which are essential for maintaining optimal operating temperatures and preventing equipment failures. As AI use increases, the challenge of maintaining efficient cooling processes becomes even more critical, both environmentally and commercially.

What role do high-efficiency motors and variable speed drives play?

One of the most effective strategies for reducing cooling-related energy consumption in data centres is the use of high efficiency motors and variable speed drives (VSDs) in controlling the operation of pumps, fans, and compressors – key elements of all cooling infrastructure.

Traditional motors in cooling systems often operate in line with outdated efficiency standards, leading to excessive electricity use and higher energy costs. Modern high-efficiency motors, such as those meeting IE4 and IE5 standards, significantly reduce energy losses by optimising electrical and mechanical performance. Compared to older models, these motors can deliver electricity savings of up to 10%, offering a rapid return on investment.

The combination of high-efficiency motors with VSDs means that motor speeds can be adjusted in real-time based on actual cooling demands, unlike conventional fixed-speed motors. This dynamic response prevents unnecessary energy use, as motors do not need to run at full capacity when cooling loads are lower. By using VSDs, data centres can reduce energy consumption from cooling systems by up to 30-50% while maintaining optimal server temperatures. Additionally, these drives help prolong the lifespan of cooling system components by reducing mechanical wear and tear, lowering maintenance costs in the long run.

The advantages of ultra-low harmonic drives

Harmonics – distortions in electrical power – are a common issue in large data centres, leading to overheating, equipment degradation, and inefficient energy usage. Another key innovation in cooling system efficiency is the implementation of ultra-low harmonic (ULH) drives. ULH drives address critical power quality issues while offering significant energy savings, particularly at partial loads, by minimising harmonic distortion, thereby ensuring cleaner and more reliable power delivery. This enhances the performance of cooling systems while reducing wear and tear on electrical infrastructure.

Data centres rarely operate at full capacity 24/7. ULH drives provide superior efficiency during partial load conditions, optimising power consumption and reducing strain on cooling infrastructure. Unlike traditional drives, ULH drives can deliver stable operation even when cooling demands fluctuate, ensuring that energy is not wasted.

On the logistics side of things, the modular design of ULH drives allows for easier installation, servicing, and future upgrades. This flexibility helps data centre operators maintain efficient cooling systems while keeping long-term operational costs manageable. Moreover, by improving power quality, ULH drives help reduce the likelihood of disruptions in sensitive IT operations, further safeguarding uptime and reliability.

Modular and future-proof cooling systems

In addition to upgrading motors and drives, data centre operators can improve energy efficiency by adopting modular cooling solutions. These systems are designed for scalability and adaptability, making them ideal for an evolving data centre industry which must keep up with increasing demand.

Modular systems allow operators to integrate new technologies without overhauling entire cooling infrastructures. Individual components – such as motors, drives, and heat exchangers – can be upgraded as more efficient models become available, ensuring continuous improvements in energy performance. This modular approach aligns with sustainability goals by allowing operators to make incremental changes rather than replacing entire systems.

A modular approach also simplifies maintenance, reducing downtime and associated costs. Furthermore, components can be recycled or repurposed, aligning with circularity initiatives and reducing environmental impact through circular principles.

This approach not only minimises waste but also enhances the overall resilience of data centre operations.

The business case for energy-efficient cooling

Investing in energy-efficient cooling technologies is not just an environmental necessity – it makes sound financial sense. By reducing electricity consumption, data centre operators can achieve substantial cost savings on energy bills. Additionally, many governments and regulatory bodies offer incentives for adopting high-efficiency motors and drives, further improving return on investment.

As customers and stakeholders continue to demand greater transparency regarding sustainability practices, data centres that prioritise energy efficiency and decarbonisation can strengthen their competitiveness in a rapidly evolving industry and meet growing computing demands, while maintaining stable operations.

As data centres continue to expand in size and complexity, energy-efficient cooling will be a critical factor in their sustainability and profitability. High efficiency motors, intelligent VSDs, and ultra-low harmonic drives offer substantial energy savings while enhancing system reliability and flexibility.