As more customers with mission critical projects look for remote testing solutions during the coronavirus lockdown, Equinix has taken full advantage of Aermec’s smarter more sustainable offering.

Following Aermec’s successful roll out of factory acceptance testing (FAT) of equipment by video link, more companies are taking advantage to beat the constraints of the UK’s lockdown as a result of the Coronavirus (Covid-19).

Equinix, one of the world’s largest data centre and colocation service providers, is the latest company to use the facility. Like Aermec, it is committed to the health and safety of employees, whilst ensuring minimal disruption for its customers.

By collaborating with Aermec, Equinix is taking advantage of video technologies, and carrying out witness testing of glycol free chillers for one of its mission critical data centre sites.

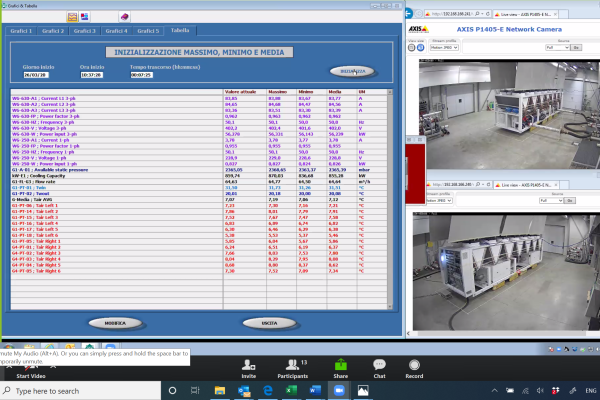

In line with the current Italian government guidelines, which permits the testing of products that have been designated of primary necessity, Aermec is monitoring the real time test screen at its factory in Italy.

A live link into the test cell enables Equinix to take part, multiple cameras provided accurate streaming and enables data to be viewed as it comes through.

“FAT testing remotely is not only helping us and our customers to beat the restrictions resulting from the pandemic, it is a smarter and more sustainable way of working,” commented Paul Lawrence, managing director, Aermec UK.

The remote links overcome geographical limitations and the test audience can be expanded as the number of participants is not restricted.

“Our customers are able to experience and fully participate just as if they were in our factory in Italy. Aermec is effectively bringing FAT tests to the customers rather than the customer to the testing laboratories,” added Lawrence.