Data centre operators across the country depend on uninterruptible power supplies (UPS) to provide the ultimate insurance that if there’s any issue with the mains electricity, their vital servers and other critical equipment will keep on running.

But without a well-maintained, quality battery system that provides the all-important emergency power when needed, the UPS itself is practically useless.

As many as 80% of UPS failures can be linked to issues with the batteries, while batteries also constitute a large proportion of the total cost of a UPS, representing a considerable investment for operators.

That’s why good upkeep is critical, as letting the battery system fall into a poor state heightens the risk to both your critical load and business continuity.

The basics of UPS batteries

While a growing number of data centres are exploring alternative solutions such as lithium-ion, the majority of UPS systems today use sealed or valve-regulated lead-acid batteries, often shortened to SLA or VRLA.

These cells are big and heavy, due to their low energy-to-weight and energy-to-volume ratios. But they do deliver high surge currents, making them perfect for providing instant backup during a temporary mains failure or to power up a generator.

Most of the VRLA batteries used in data centres will have a 10-year design life, which suggests that the battery will last for 10 years. But there’s one important caveat. That assumption is based on ‘perfect’ operating conditions.

Of course, there’s no such thing as a perfect operating environment. There are simply too many factors that can influence a battery’s lifespan, and over time, performance will inevitably reduce.

Guidelines issued by EUROBAT, the Association of European Automotive and Industrial Battery Manufacturers, state that a battery reaches its end of service life when capacity drops below 80% of its original value.

Even before allowing for any external influences that affect lifespan, the operational capacity of a 10-year design life battery will drop below 100% at year six. Capacity will continue to fall to around 80% over the remaining four years, while the autonomy of the UPS will reduce too.

That’s why it’s become commonplace to proactively replace 10-year design batteries in service year seven or eight. It takes into account all the factors that reduce lifespan, while leaving enough of a safety margin to mitigate any drop-off in performance.

What reduces a battery’s lifespan?

Several factors impact the length of UPS battery lifespan, such as the frequency and depth of discharge. Every time you discharge a battery, it slightly reduces its capacity, although a partial discharge does have less impact than fully draining the cells.

Operating voltage is another issue. Overcharging above the manufacturer’s recommended guidelines produces excessive hydrogen and oxygen, which will dry the batteries out over time.

Conversely, undercharging can lead to sulphate crystals forming on the plates and within the electrolyte. Known as sulphation, this condition is common with stop-start battery applications like a UPS. It increases internal resistance and results in a longer charging cycle.

There’s ripple current, where the AC ripple generated by the UPS’ rectifier, charger, or inverter can cause overheating, which speeds up the rate of deterioration.

Poor alignment of the separators and plates during the initial design and installation process can cause something called top mossing, where a crystalline moss forms and can see the cell start self-discharging.

But by far the most common cause of premature battery failure is high ambient temperature – the higher the temperature, the quicker the chemical reaction, which increases water loss and corrosion.

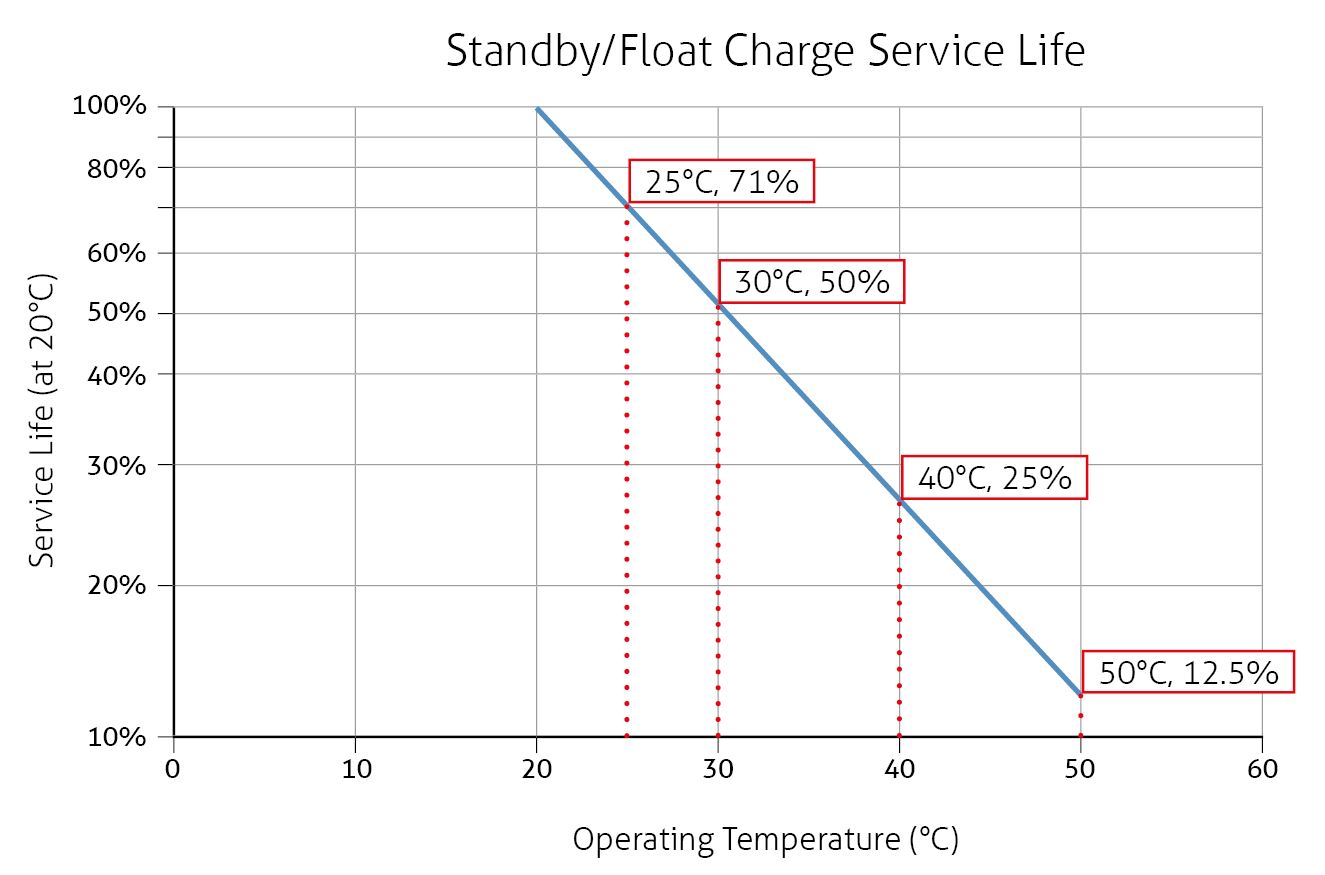

A VRLA battery has a rated capacity based on an optimum operating temperature of 20-25oC. For every 10oC temperature increase, it’s generally accepted the service life will halve.

Preventing premature battery failure

The good news is that data centre operators can take several steps to maximise the service life of their UPS batteries. It all boils down to proactive maintenance, monitoring, and testing.

At a bare minimum, each battery should be manually checked at least once a year. Such basic physical checks inspect the terminals for any signs of corrosion, leaks, cracks, or swelling. It’s also a chance to tighten any inter-cell connections.

It should be noted that most of the modern UPS systems deployed in data centres will incorporate their own sophisticated battery care systems, which monitor and record measurements like the number of cycles or float voltages. They will also automatically run regular tests, protect against slow discharges and ripple currents, and provide a range of recharge options.

Naturally, data centres should invest in more advanced forms of battery testing too. One option is impedance testing, a non-intrusive way to build up a history of each individual cell. It involves applying an AC current via probes attached to the terminals, and if you carry it out annually, it’s relatively easy to compare the results and spot any worrying signs of deterioration.

Impedance testing doesn’t require the batteries to be taken offline – but it only provides a broad indication of their condition, so isn’t a perfect solution by any stretch.

An alternative is discharge testing, which is often referred to as load bank testing. This interrogates your batteries at normal and peak loads, showing which cells hold their charge and which are nearing the end of their service life.

However, load bank testing does take the batteries out of service. While typically this tends to be for just a few hours, it can stretch to several days in the worst-case scenario.

If you’re looking for a middle way between these two approaches, you’ve got partial discharge testing. The batteries are discharged by 80%, so you still have 20% capacity to call upon if the mains supply is interrupted.

Of course, another way of maximising UPS battery lifespan is ensuring they operate within their optimum temperature range of 20-25oC, either with sufficient air conditioning in the IT room or by housing them in their own standalone battery room.

You should install UPS batteries in a well-ventilated area free of dust or moisture, ideally away from direct sunlight. It’s advised to leave at least a 10mm gap between battery blocks to ensure adequate ventilation.

Doing so takes into account that the battery casing will expand slightly as and when it gets warmer. This gap also allows heat to dissipate, which reduces the risk of overheating and subsequent likelihood of thermal runaway.

Finally, it’s worth noting that even unused UPS batteries will automatically discharge small amounts of energy. So if you plan on storing batteries for a prolonged period before using them, keep them at a maximum temperature of 10oC and top up charge them every few months.

Proper preparation is key

With so many variables that can influence the rate of battery deterioration, it’s clear data centre operators need to have robust monitoring, maintenance, and testing regimes in place.

It also highlights the importance of following industry-accepted best practice, such as proactively replacing 10-year design life batteries in year seven or eight.

Failure to do so is an unacceptable gamble, particularly in a mission-critical environment like a data centre, where even a short period of unplanned downtime comes at a huge cost.