ETAP and Schneider Electric have jointly introduced what they’re calling the world’s first digital twin capable of simulating every facet of an AI Factory’s power usage, from the grid right down to chip level.

Unveiled at NVIDIA’s GPU Technology Conference, the solution is set to leverage NVIDIA Omniverse technology to help data centre and AI operators better manage the rising demands of their infrastructure.

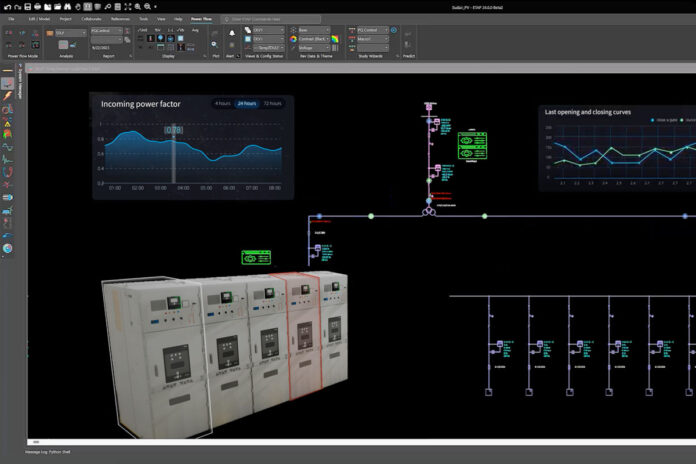

How the digital twin works

It’s no secret that AI workloads continue to place a significant burden on data centres, with advanced training and inference processes demanding high rack power densities. In fact, reports suggest that AI training tasks use 10-15 times more power than traditional data centres were designed to handle.

That means it’s not always immediately obvious to operators what they need for their AI-ready data centres, nor how they can effectively manage that growing demand for power. That’s where the new digital twin from ETAP and Schneider Electric comes in.

By integrating ETAP’s advanced power system design expertise with NVIDIA Omniverse, the new digital twin offers real-time modelling, ‘what-if’ scenarios, and predictive maintenance strategies that claim to deliver better reliability, sustainability, and cost savings.

Crucially, this collaboration introduces a ‘Grid to Chip’ approach – aiming to understand and optimise power consumption not only at the rack but also at the chip level. With AI workloads ever-growing, precise control over load behaviour could prove vital to operators’ bottom lines.

“As AI workloads grow in complexity and scale, precise power management is critical to ensuring efficiency, reliability, and sustainability,” said Dion Harris, Senior Director of HPC and AI Factory Solutions at NVIDIA.

“Through our collaboration with ETAP and Schneider Electric, we’re offering data centre operators unprecedented visibility and control over power dynamics, empowering them to optimise their infrastructure and accelerate AI adoption while enhancing operational resilience.”

‘AI Factory of tomorrow’

By opening the door to enhanced system planning, dynamic power flow analysis, and predictive maintenance, ETAP and Schneider Electric believe data centres of the future will not only cut operational costs but also bolster efficiency, reliability and sustainability, paving the way for what they call the ‘AI Factory of tomorrow’.

“This collaboration represents more than just a technological solution,” said Tanuj Khandelwal, CEO of ETAP.

“We’re fundamentally reimagining how data centres can be designed, managed, and optimised in the AI era. By bridging electrical engineering with advanced virtualisation and AI technologies, we’re creating a new paradigm for infrastructure management.”

Pankaj Sharma, Executive Vice President for Data Centers, Networks & Services at Schneider Electric added, “Collaboration, speed, and innovation are the driving forces behind the digital infrastructure transformation that’s required to accommodate AI workloads. Together, ETAP, Schneider Electric, and NVIDIA are not just advancing data centre technology – we’re empowering businesses to optimise operations and seamlessly navigate the power requirements of AI.”