With today’s demand for ‘always on’ digital services, how can operators ensure customers aren’t left disappointed? Marc Garner, vice president, Secure Power Division, Schneider Electric UK & Ireland, examines the methods deemed essential for dodging that dreaded downtime, as well as ways to increase energy efficiency and security.

Today’s economy has become dependent on the continuous availability of 24/7 digital services, which in almost every case are delivered by an ecosystem of data centres that range from massive hyperscale cloud facilities down to smaller, localised edge computing solutions.

Downtime is the curse of any business reliant on digital technology and where mission critical applications such as those used in healthcare are concerned, power outages and interruptions to service cannot be tolerated. New and advanced surgical operations, for example, using robotic instruments will utilise video streaming to deliver images to doctors in an adjoining room. Data collected from scanning equipment will need to be aggregated, backed up and placed within the patient’s digital health records in real-time. Moreover, the scanning equipment itself will need to be protected from power surges or outages.

All of these examples are dependent on connectivity, availablity and resilient IT equipment. The slightest malfunction could mean loss of information, changes in treatment, or worse, loss of life. It follows, therefore, that the data centres and network infrastructure systems supplying such services must become ever more reliable, ensuring that any potential IT issues do not result in unacceptable levels of downtime.

Power at the edge

This is especially true of the Uninterruptible Power Supply (UPS); a battery-based backup system that takes over instantaneously in the event of any disruption to mains power. Not only must a UPS be reliable in its operation, it must also be energy efficient, cost-effective to run and easy to maintain.

For edge computing solutions, those which are much smaller in size but also infinitely more numerous than hyperscale or regional data centres, this presents a particular challenge for operators. Especially as the advent of 5G services, hybrid IT deployments and new Internet of Things (IoT) applications is only expected to increase in number and geographical spread.

Given their size, diverse locations and number, edge data centres will almost never have t10rained IT personnel permanently on-site. Management and maintenance, therefore, must be achieved remotely through a combination of cloud-based software, 24/7 access to real-time data and by acquiring the expertise of specialist service partners or Managed Service Providers (MSPs).

Moreover, physical security remains a critical concern when ensuring resilience at the edge and finding a way to deliver all of these critical attributes in a cost-effective way has previously been a major challenge for the industry.

Technologies to drive lower cost of operation

Fortunately, this challenge is being met through advancements in new technologies including artificial intelligence (AI) software, machine learning and lithium-ion (Li-ion), which help the operator to drive uptime, power availability and energy efficiency through every critical IT deployment.

The latest evolution of cloud based data centre infrastructure management (DCIM) software, for example, provides greater levels of resilience and uptime for the user. Furthermore, within new Li-ion UPS solutions, developments in modular construction have enabled backup power systems to be deployed faster and with the specific power rating for the task in hand.

In mid-range applications, for example, power modules of typically 10 or 20kW capacity can be combined within the same chassis to deliver a power rating of up to 100kW. This is particularly useful for edge applications where the load sizes can vary from one location to another, and where a “one size fits all” approach will be far from cost effective. Matching the UPS to the load in a modular undoubtedly delivers a far better solution to the customer in terms of cost.

The modular approach also greatly simplifies maintenance. The ability to swap out key components, such as the batteries, a system controller or a charging module, and replace it with another standard part minimises downtime without incurring large labour costs. Depending on the function of the module, some components can even be swapped out without bringing the UPS off-line at all.

Key benefits of Li-ion

Lithium-ion technology is of particular benefit in UPS applications, despite the fact that it still commands a small up-front cost premium over traditional valve regulated lead-acid (VRLA) batteries. This cost, however, is diminishing over time due to technology advancements and an increase in volume through the use of large format Li-ion battery systems for electric vehicles and energy storage applications.

Li-ion batteries are smaller in size, both in terms of weight and footprint, than a lead-acid battery of equivalent rating. Typically, an Li-ion battery will take up half as much space in a UPS and is around 50% of the weight of its alternatives. They can also withstand many more charge/recharge cycles and can consequently deliver twice the operational life.

Over the lifespan of a UPS, the total cost of ownership (TCO) of a Li-ion battery works out far less than one using lead-acid. One such study conducted by Schneider Electric’s Data Centre Science Centre found that over a 10-year period, Li-ion delivered a TCO that is between 10% and 40% less than an equivalent UPS using VRLA.

Software and analytics

Due to their chemical makeup, Li-ion batteries can be sensitive to overcharging. Consequently, today’s UPS systems incorprate advanced battery management systems comprising sensors, switches and microcontrollers as standard, all of which is managed by software. This can be further exploited by cloud-based DCIM systems, which allow greater levels of remote management for owners and operators.

With its comprehensive monitoring abilities, real-time reports can be delivered securely to any smart-device, so that unexpected problems can be identified and addressed either before, or as soon as they occur. This allows service personnel to be proactively despatched to any location both quickly and cost-effctively. For the most distrbuted edge data centres, this is of vital benefit as it allows numerous edge or IT locations to be maintained by a team of remote service personnel, including third-party MSPs.

Power

Reducing power consumption while guaranteeing uptime is also of great concern for data centre operators. Many UPS systems offer an economy mode which improves the efficiency of the unit without impacting the overall reliability.

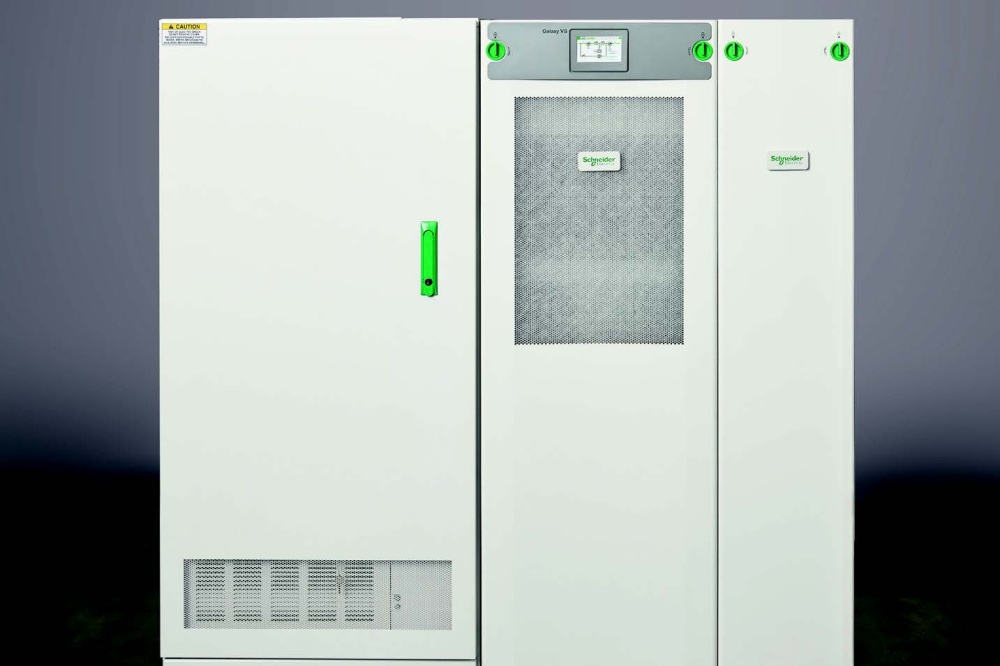

In the latest power protection solutions, such as the Schneider Electric Galaxy VS UPS, the efficiency of the system can be boosted from 97% in its normal operating mode to 99% in economy mode. This may seem like a small difference but over time, the cost savings can be significant.

By some estimates, using economy mode can yield cost savings, in terms of unused electricity, that equate to the acquisition cost of the UPS after only two years’ use. Over a 10-year period, the total savings derived from using a Li-ion UPS in economy mode can be as high as 50%, which is incredible.

When tasked with ensuring the continuous delivery of digital services in both a cost-effective and resilient way, UPS systems incorporating Li-ion batteries and cloud-based management tools are essential; providing greater reliability, increased energy efficiency and higher levels of availability for today’s always-on businesses.