The huge shift to online living caused by the pandemic has created massive demand for data centre capacity. Thoughtful data centre operators are turning to modular data centre design and construction approaches to ensure that their capital investment remains in line with real – not forecast – demand for the resultant services.

Taking a modular approach to data centre infrastructure such as power and cooling facilities has the added advantage of enabling equipment to be configured and tested off-site and then added quickly as needed.

Modular data centres are being used in many contexts. They are shipped into areas that have been struck by natural disasters to provide emergency computing power. They are being used to add capacity to existing data centres without interrupting core systems. There is interest in using modular approaches to build hyperscale data centres. And modular data centres may also be particularly suitable for adding regional capacity, and capacity at the edge of large networks.

This localisation minimises the time it takes for data to reach a data centre, get processed, and return to its origin, which is important for latency-sensitive applications, such as 5G and machine-to-machine communications.

Equipment providers need to offer flexible, modular systems that can be configured for edge, regional and hyperscale data centres, which also meet all the local regulations and requirements wherever they are installed globally.

Power Optimised Design Solutions

One approach to doing so is to use Power Optimised Design Solutions (PODS), low- and medium-voltage generator sets (gensets) that offer high performance, reliability, robustness and safety. PODS are modular and can have their radiators mounted on the generator base-frame, simplifying handling and installation.

PODS are designed to be delivered complete and then mounted on an external concrete slab, with all the customer’s options already connected and tested, enabling rapid installation. PODS can be racked or stacked, so that capacity can be added as backup power needs grow.

As data centres proliferate, especially at the edge of the network where they will be installed in office parks and mixed-use areas, controlling the noise they make becomes critical to gaining planning approval and to being a good neighbour once in service. To ensure this, PODS can be fitted with soundproofing panels made of mineral wool with an M1-class fire rating covered by glass fibre. Noise suppression is essential, to limit noise to 85dB(A) measured at 1m away from the source in most applications, and to 75dB(A) or even 65dB(A) for use on more sensitive sites.

For local or edge data centres that draw up to 5MW, PODS can be packaged in a standard 20 foot container, with a skin-tight enclosure that can be customised to user requirements, or with a canopy. They’re compact and available on a short lead time.

Regional data centres that need up to 25MW of backup power can be served with modular PODS, which are available in a 40-foot shipping container, for ease of transport and integration with data centres that use racks and stacks of such containers to house server and networking equipment. Modular PODS are also available in skin-tight enclosures.

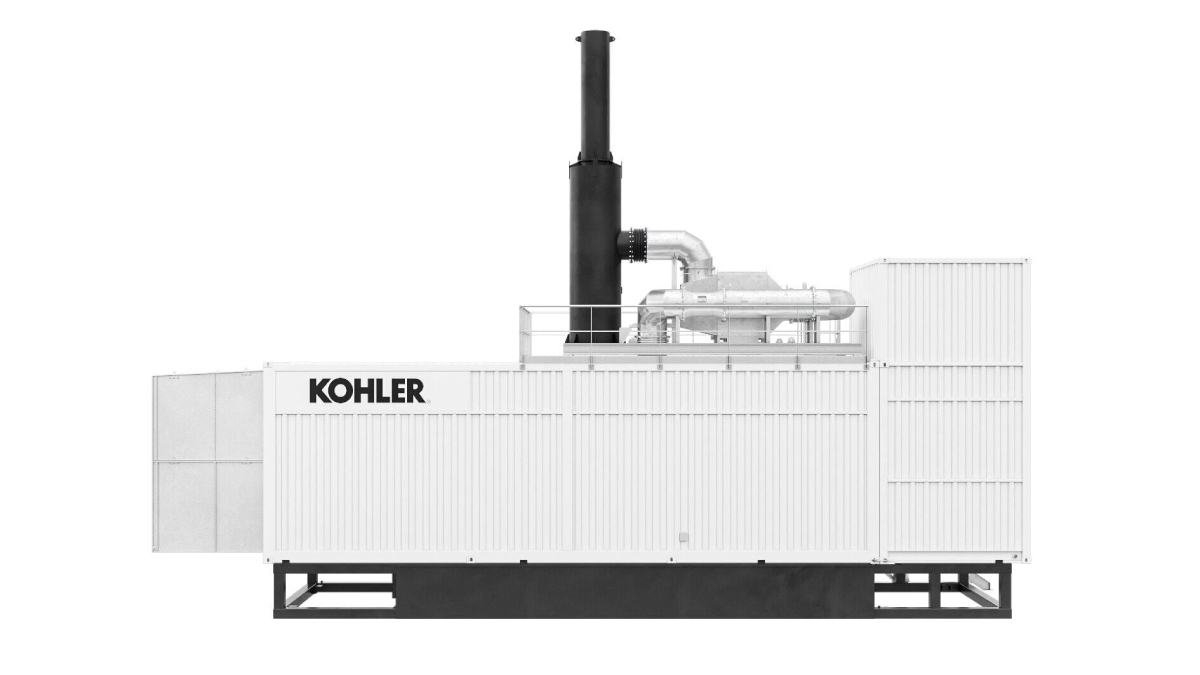

Finally, for hyperscale data centres that need up to 500MW of backup power, Kohler offers Density PODS. These are packaged in 45 foot containers or in walk-in enclosures that have enough internal space to allow for the internal cooling necessary to accommodate very high power gensets, while also allowing operator access. These walk-in PODS are a good choice for these large-scale operations, as they give technicians access to all the most important aspects of the genset for maintenance.